Stretch film is one of the most durable packaging materials, ideal for packaging of goods in transportation..

In the production of stretch film Sirius Extrusion company have evolved from three-layer to 5-layer structure. This is, also as an unique recipe and use the most modern equipment helped create one of the most durable packaging materials. Stretch film allows ensure the safety of cargo during transport, storage, protection from the external environment, and is also suitable for food packaging.

Using of stretch film helps to facilitate handling and to save time on product packaging, and high resistance to puncturing, tearing and bumping explains the reason of its rapidly growing market demand.

Today no one industry, which would not have used stretch film, great quality of this packaging solution praised our core customers: Coca-cola, PepsiCo., Danone, IDS Group and others.

UTS and TS are newest developments of Sirius. These films enable to reduce grammage of the packaging per pallet wrapped. The films 8 to 12 mkm are easily replacing regular hand film with thickness 17 to 23 mkm. Costs saving and less foot print as result. Mechanical properties of the films exceed properties of a prestretched film.

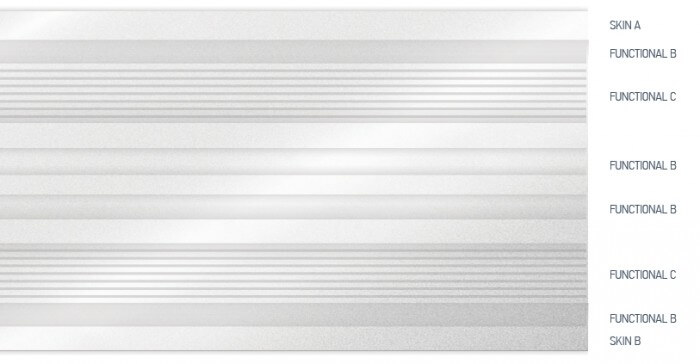

structure of stretch film

The multilayer structure of stretch film provides an opportunity to make a film with certain physical and mechanical properties and the adhesive side of the web. The material of each layer of the film are different brands of linear low density polyethylene (LLDPE).

stretch film

The principle of operation of stretch film is simple: by pre prestretch (stretching) after wrapping pallet load, the film tends to return to its original state, causing the load is securely attached to the pallet and suitable for transporting or handling operations.

Stretch film is used for food packaging and packaging of various goods. Pallet stretch film for hand made (packing cargo holds hands) and machinery packing (using packaging machines – Palletizer).

Packaging stretch film has high physical-mechanical

characteristics (reverse recovery after 300% elongation) and more cost-effective in its using.

of stretch film

transparant

white

yellow

green

blue

black

stretch film

properties

«Colchuga» or nano-stretch film – innovative product of our company.

Nano-stretch film has a 31-layer and manufactured by unique technology nano-layer, whereby the thickness of the layers of the film is measured in nanometers (10-9).

It is possible to create an incredibly strong and lightweight packaging, the elongation properties which help to save up to

50% of the packaging material compared to conventional film.

Sirius Company is one of the few in Europe has nano-layer technology. Using nano-stretch film production of Sirius, you increase the efficiency of your business and make your contribution to environmental protection.

structure Colchuga

The multilayer film structure provides incredible strength of the packaging material and its high extensibility.

features

Given the functional purpose of the stretch film is stretch and hold the load on the pallet,

its strength is classified into 5 basic types:

| Thickness, mm | Length winding, m | Width of web, m | Operating range stretching % | Maximum strength, MPa

|

Max. relating elongation, %

|

RS

Recommended for packaging mild manual handling

| 12-23 | 150-5000 | 200-2000 | <100 | 20 | 20 | 350 | 500 |

MS

MS

Recommended for packaging

using palletizer not equipped

pre-stretching mechanism

| 17-35 | 1000-2000 | 200-2000 | <150 | 25 | 25 | 400 | 600 |

SPMS

Recommended for high-speed automatic packaging palletizer equipped with pre-stretching mechanism

| 17-35 | 1000-2000 | 200-2000 | <250 | 40 | 25 | 500 | 650 |

COLCHUGA

Recommended for high-speed automatic packaging palletizer equipped with pre-stretching mechanism

| 12-25 | 1000-2000 | 200-2000 | <350 | 45 | 25 | 550 | 700 |

The high technical level of production equipment guarantees production of qualitative stretch film corresponding to requirements of technical standard Technical Conditions TU 25.2-31617387-001-2009.Products Sirius – certified according to UkrSePrO, ISO 9001, meet TU and has sanitary-epidemiological conclusion on the safety of its use in the food industry. Stretch film is recommended to store in enclosed dry rooms with a temperature of 0 ° C to +35 ° C. Stretch film is desirable to use at temperatures from +10 ° C to +35 ° C. On the tack stretch film greatly affected by ambient temperature (very low or very high temperature), direct sunlight, rain, dirt and dust. Given the geometric and physical parameters of the load model palletizer at your company, Sirius experts recommend the most optimal type of stretch film both on strength and thickness.

stretch film

- The film has high physical and mechanical function and reverse recovery after 300% elongation, which ensures cost-effectiveness of the package.

- High stretch film resistance to puncture, tear and impact.

- Using stretch film helps save time on product packaging.

- Through the use of nanotechnology, we have created an incredibly easy film Colchuga (layer thickness measured in nanometers (10-9) – allows for 40% reduction in weight of the film on the packaging.