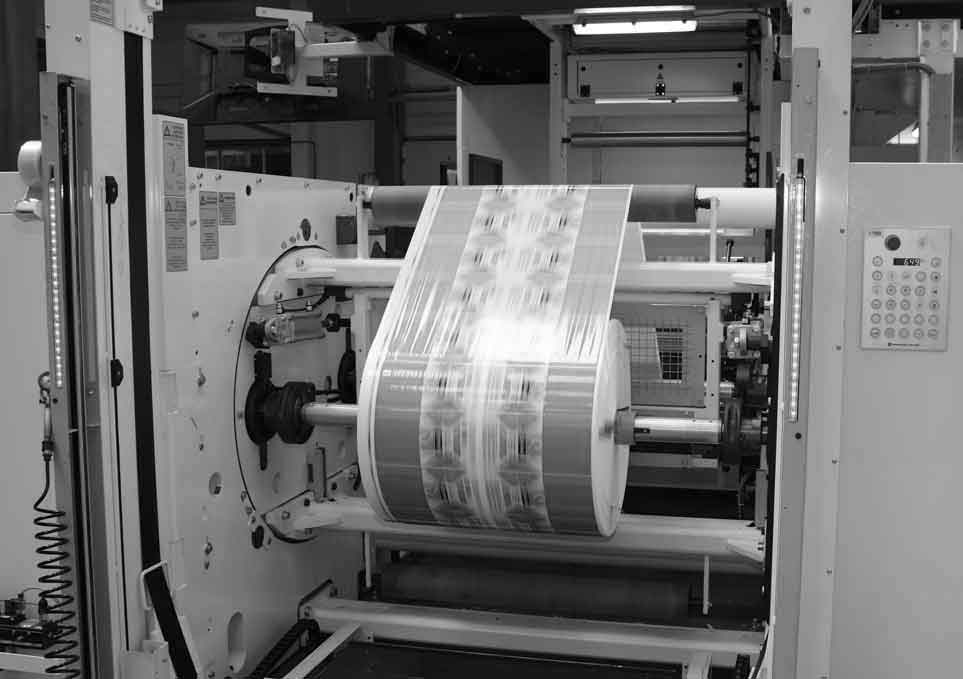

Our printing house is equipped with modern equipment that allows us to fulfill orders for the manufacture of packaging with a printed image.

We use flexographic printing with up to 8 colors. It is flexo-printing that allows us to be flexible and to complete orders quickly and in short runs, while maintaining high quality standards.

- flexibility and high speed of printing;

- a fleet of modern printing machines from leading world manufacturers;

- high image quality with rich colors;

- highly professional prepressing;

- lamination – creation of a multilayer film with the image between the film layers;

- re-print – selective application of lacquer (varnish).

Thanks to flexo-printing technology, we can quickly reconfigure from one order to another. Thus, we are able to carry out short print runs without losing the high quality of the image itself and our customers can order packaging more often without increasing their inventory, which, accordingly, provides significant savings.

Our printing machines can print images in up to 8 colors. The entire printing process is closely monitored by our highly qualified specialists. During the printing process, color saturation and compliance with approved sample are monitored. Also, using the error detection system, we can monitor the quality of the image and the material itself online and immediately respond by taking corrective actions, if necessary. In this way, we can guarantee our customers a consistently high quality flexographic printing.

Modern equipment and highly professional prepressing allows us to print images with a high screen ruling (up to 150 lpi), which means good and smooth transitions between the shades and technical capability to transfer the images to polymer film.

In order to achieve good results and to obtain high quality flexo-printed images, we have two essential elements: high-tech equipment and professional prepressing.

Professionals working in our Design Office can embody all the customer’s ideas as to transferring any individual image to polymer film using their skills, expertise and modern state-of-the-art equipment.

Each completed project is saved in our database and we can use it to speed up order execution, when necessary.

To streamline the prepressing, we provide our customers with primary information on the requirements to design specifications.

Our production facilities also feature a laminator from the world’s leading manufacturer – COMEXI. The lamination method allows us to create multilayer packaging films, such as top covers or flow-pack films, to achieve the desired properties, depending on the requirements to the product storage and the aesthetic design of the packaging.

Lamination also allows placing the image between layers of film, thus protecting it from external exposure and preserving the brightness and saturation of colors.

For the most demanding customers, we offer selective lacquering (varnishing) over the printed film. This is possible thanks to using the re-print function, which allows creation of a printed film, where some elements stand out from the whole composition. Thanks to selective lacquer application, we can create packaging with various optical and tactile effects, such as “soft touch” and “paper touch”.